How AI Is Rewriting Aerospace Design for the Better

Explore how AI is revolutionizing aerospace design, enhancing efficiency, cutting costs, and paving the way for innovative advancements.

AI is transforming aerospace design by making it faster, cheaper, and more efficient. Here’s how:

- Speeds up design: AI reduces design time from months to hours, enabling rapid prototyping.

- Improves quality: AI-generated parts have up to 10x lower stress factors and are 40% lighter.

- Enhances testing: Tools like digital twins predict performance and maintenance needs accurately.

- Discovers new materials: AI boosts material discovery by 44%, leading to stronger, lighter aerospace components.

- Cuts emissions: AI-designed parts, like Airbus’s cabin partitions, save up to 465,000 metric tons of CO2 annually.

Quick Comparison

| Aspect | Traditional Method | AI-Driven Approach |

|---|---|---|

| Design Time | Weeks to months | 1–2 hours |

| Component Weight | Baseline | Up to 40% lighter |

| Stress Factors | Standard | Up to 10x lower |

| Material Discovery | Slow | 44% faster |

| CO2 Emissions | Higher | Significant reductions |

AI is reshaping aerospace by cutting costs, improving safety, and driving innovation, all while keeping human oversight critical to the process.

Fusing Real-Time AI With Digital Twins

Core AI Tools in Aerospace Design

AI reshapes aerospace development by improving design processes, testing methods, and material innovation. Its tools make the industry faster, more efficient, and more precise.

AI Design Optimization

AI-powered tools can analyze thousands of design variations while managing complex constraints, leading to designs that often surpass those created using traditional techniques. For example, AI inspection systems can now evaluate turbine blades in minutes, significantly reducing defect rates compared to older methods [6].

"AI has become fundamental in the management of safety, part design, inspection processes, maintenance, repair, and overhaul (MRO), and fuel efficiency" [5].

In addition to design optimization, AI transforms testing processes through technologies like digital twins and advanced simulations.

Digital Testing and Modeling

Digital twins and AI-based simulations are revolutionizing product development. Currently, 75% of large enterprises invest in digital twins to expand their AI capabilities [7].

"AI enhances predictive maintenance and digital twins in several ways, most notably by its ability to enhance data analysis, streamline operations, and yield actionable insights, ultimately leading to increased operational efficiency and decreased costs" [8].

Johannes Maunz, vice president of AI at Hexagon, highlights how AI simplifies the process of keeping digital twins updated:

"AI reduces the time and cost in keeping a digital twin up to date" [8].

This combination of predictive maintenance and operational insights helps companies cut costs and improve efficiency.

New Materials Discovery

AI is speeding up the discovery of advanced materials for aerospace use. Research shows a 44% boost in discovering new materials and a 39% increase in patent filings [9].

"We stand at the brink of groundbreaking advancements driven by AI and high throughput data generation" [10].

One example is DRAGONS, an AI platform that designs futuristic superalloys. It evaluates material properties, optimizes compositions, and reduces experimental costs [10].

The impact of AI on material discovery can be seen in the table below:

| Metric | Traditional Approach | AI-Assisted Approach | Improvement |

|---|---|---|---|

| New Materials Discovered | Baseline | +44% | Faster discovery rate |

| Patent Filings | Baseline | +39% | Increased innovation output |

| Product Prototypes | Baseline | +17% | More practical applications |

| Material Testing Time | Hours/Days | Minutes | Huge efficiency improvement |

Current AI Projects in Aerospace

AI is revolutionizing aerospace by improving fuel efficiency, speeding up design processes, and advancing military capabilities.

Fuel Use Reduction

OpenAirlines' SkyBreathe® On Board Direct Assistant is helping airlines cut fuel consumption by up to 30%. It achieves this by identifying the most efficient flight paths [11].

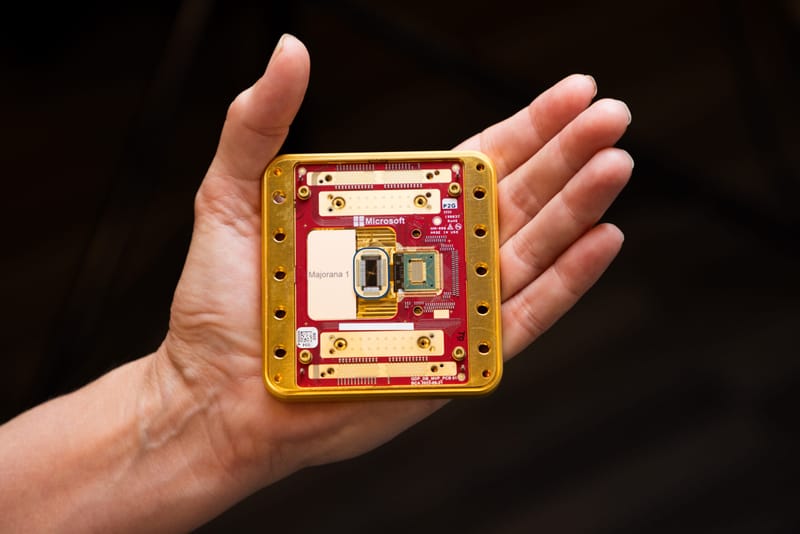

Faster Design Testing

At NASA's Goddard Space Flight Center, AI has been used to design a 3D-printed titanium mount in just 1–2 hours, with a prototype ready in under a week [2].

"You can perform the design, analysis and fabrication of a prototype part, and have it in hand in as little as one week. It can be radically fast compared with how we're used to working."

– Research Engineer Ryan McClelland [2]

| Metric | Traditional Design | AI-Assisted Design | Impact |

|---|---|---|---|

| Design Time | Weeks to months | 1–2 hours [2] | Over 90% faster |

| Weight | Baseline | Up to 66% lighter [2][12] | Saves up to $1M per kg in launches |

| Stress Factors | Baseline | 10× lower [2] | Improved safety and reliability |

This rapid design process illustrates AI's growing importance in aerospace innovation.

Military Aircraft Improvements

AI is also reshaping military aviation. Shield AI's Hivemind AI pilot system can perform tasks across various platforms, including quadcopters, fixed-wing aircraft, and even simulated F-16 dogfights [13].

"AI pilots will revolutionize battlefields and commercial aviation at a scale greater than the self-driving movement reshaping our highways."

– Shield AI [13]

In January 2025, Shield AI's V-BAT system began training with Ukraine's Unmanned Aircraft Systems Forces. This system showcases AI's ability to operate without GPS, communication links, or human pilots, making it a game-changer in military reconnaissance [13].

Risks and Safety Concerns

AI is reshaping aerospace design, but it also presents challenges. Industry leaders prioritize ensuring safe and responsible use.

Human Skills vs AI Tools

Delta Air Lines provides a great example of how humans and AI can work together effectively. They use AI to predict flight disruptions, but human dispatchers still make the final calls [15]. As one expert put it:

"AI is a highly intelligent assistant, but humans remain the final authority in aviation decision-making" [15].

Lufthansa Technik takes a similar approach. They use AI for predictive maintenance, analyzing aircraft health data to flag potential issues. However, engineers have the last word, considering on-the-ground realities. This balance has boosted aircraft availability by up to 35%, all while keeping human judgment at the forefront [14].

| Role | Human Responsibility | AI Support |

|---|---|---|

| Design Engineers | Approving final designs and ensuring safety | Rapid prototyping and advanced calculations |

| Maintenance Crews | Making service decisions and quality checks | Predicting component failures and wear analysis |

| Flight Operations | Planning routes and managing emergencies | Analyzing weather patterns and optimizing fuel |

This collaboration between humans and AI is essential, but safeguarding design data is equally critical.

Design Data Protection

Tools like Neural Concept Shape (NCS) show how AI can dramatically speed up processes but also highlight the need to protect sensitive design data [4]. Here are some key measures:

- Authentication Controls: Use multi-factor authentication for teams managing AI models [16].

- Data Monitoring: Deploy tools to detect unusual data flow patterns [16].

- Model Protection: Encrypt AI models and their outputs and use containerization for added security [16].

These steps ensure that AI-driven efficiency doesn't compromise data integrity.

Military AI Guidelines

The Department of Defense has laid out strict ethical principles for using AI in military settings. These guidelines focus on accountability and reliability, ensuring that AI systems can be safely shut down if they act unpredictably [17]. Defense Secretary Mark Esper emphasized:

"AI technology will transform future battlefields, but nothing will change America's steadfast commitment to responsible and lawful behavior" [17].

Military organizations follow rigorous testing protocols and maintain human oversight of AI systems. This includes frequent legal reviews to ensure compliance with international law and comprehensive training for personnel working with AI tools [18]. To establish these principles, the Defense Innovation Board spent 15 months consulting with experts from various fields [17].

Addressing these risks is essential to fully and safely realize AI's potential in aerospace design.

Next Steps for AI in Aerospace

With safety measures in place and initial challenges addressed, aerospace companies are planning the next phase of AI-driven advancements. AI has already proven its value, and the focus is shifting toward future designs and operational improvements.

Upcoming Design Changes

AI is reshaping aerospace design in previously unimaginable ways. By 2033, the market is expected to reach $34.1 billion, growing at an annual rate of 43% from $1.9 billion in 2025 [20]. One key area of focus is creating specialized components that are up to two-thirds lighter and stronger than traditional materials, enabling new possibilities in aerospace engineering [19].

Expert Opinions

Recent partnerships highlight the rapid impact of AI on the industry, with significant performance gains reported in several key areas:

| AI Application | Performance Gain |

|---|---|

| Supply Chain Forecasting | 10–20% improvement in accuracy |

| Inventory Costs | 5% reduction |

| Revenue Growth | 2–3% increase |

| Design Time | Up to 10,000× faster |

Lilli Smith from Autodesk shares her perspective on AI's role in enhancing human capabilities:

"It's a fascinating opportunity to think in new ways. People think it's going to take away their jobs but it's going to make them so much better." [1]

These developments pave the way for broader adoption and practical applications across the aerospace sector.

Getting Started with AI Design

To kick off their AI initiatives, companies can take these important steps to address opportunities while managing risks:

- Set Clear Goals: Define specific targets for efficiency and performance improvements [3].

- Strengthen Data Infrastructure: Invest in secure and scalable systems to support AI integration [4].

- Prioritize Quality Control: Use AI-driven inspection tools while maintaining human oversight [3].

Organizations that follow these steps often see measurable benefits, such as a 5% reduction in inventory costs and up to 3% revenue growth [3]. With AI expected to automate 40% of aerospace workday tasks [3], companies need to find the right balance between automation and human expertise to ensure the safe and effective use of these technologies.